Atwell Overspeed Governor

As a primary component in the safety of the lift, the existing over speed governor should comply with the current standards in operation and accuracy and if there is any doubt then they should be replaced.

Key Features

- Installation within the lift machine room

- Design to operate “Fail Safe”

- Works with an 8mm Governor rope

- Combines proven drop jaw technology with Scott Russell Linkage mechanism

- Will generate a pull in force of between 300 and 600N

- Will not disengage if the counterweight bounces back up the shaft

- Does not require any external force to generate the braking force

- Speed Range 0.1m/s – 7.0m/s

- Requires a minimum tension weight of 15kgs with lockdown which is much smaller than conventional over speed governors

- 300mm Pulley

- Designed to work in conjunction with the VG family of safety products. But can be used to operate other safety gears requiring less than 600N to function

- Can be used to monitor uncontrolled movement and provide the signal to operate any electro-mechanical braking device

- When used in conjunction with bi-directional VG safety Gears can be used to provide both over speed and uncontrolled movement protection with doors open

- Can be used to monitor uncontrolled movement and provide the signal to operate any electro-mechanical braking device

- Can be used to operate the VG rope brake instead of the UMD control box

- When used with other VG safety products it will provide full compliance with all the latest regulations of EN81-1:1998+A3:2009

Atwell VG Rope Brake

The VG rope brake is a versatile unit that can be used as either a single or bi directional brake and is CE certified by BSI.

The brake operates on the lift ropes and is designated as a “movement prevention” or “speed reducing” means in compliance with EN81-1 1998 clause 9.10. The VG rope brake combines the proven technology of “drop-jaw” type governors with the patented VG linkage mechanism. The brake operates in a similar manner to a VG safety gear except that it has one fixed jaw and one moveable jaw or “drop-jaw”.

Key Features:

- Provides over-speed protection in both directions

- Prevents uncontrolled movement of the lift with doors open when used with a UMD-SRB01 controller

- Can be mounted either side of the traction sheave in any position – horizontally, vertically, at any angle and even inverted

- Its electromechanical design means it is fail-safe

Atwell VG Safety Gears

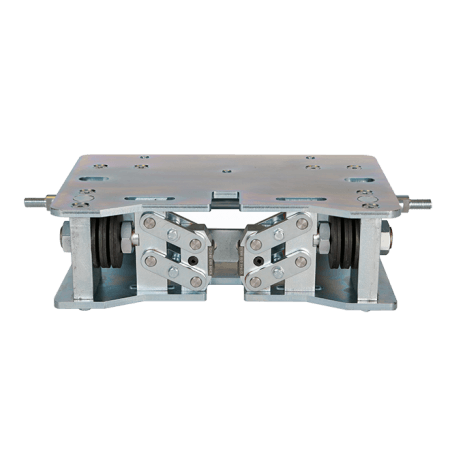

VG Safety Gears consist of a pair of end assemblies, which can bolt directly to the buffer channels or car frame. Each end assembly has two spring loaded linkage mechanisms, which carry and engage the friction gibs. The linkage mechanisms are designed to centralise the safety gear when it is engaged. This feature, in conjunction with large running clearances, means that VG Safety Gears can be used with spring loaded roller guide shoes, sliding shoes or solid rollers.

Key Features:

- 6 mm running clearance both sides – suitable for roller guide shoes or sliding shoes

- Certified for both lubricated and dry rails on class one guide rails

- All single models can be duplexed to double their braking capacity

- VG safety gears can be inverted to prevent “upward falling”. Either tandem mounted or separately mounted

- Special “dual acting” safety gear for upward and downward protection

- Surface mounted for ease of design and installation

- Simple and accurate braking force adjustment to suit on-site conditions

- Rail widths 9 to 19 mm as standard – other widths to special order

Product Range

Customer Help & Support

All Rights Reserved | Whitesmith Solutions Ltd