Blain Hydraulic Lift Components

Genuine Blain Hydraulic Components for Lift Maintenance, Repair and Modernisation

Whitesmith Solutions is the trusted supplier of Blain hydraulic components, delivering across New Zealand, Australia and throughout the South Pacific, with reliable local stock and expert support. Our extensive range of genuine Blain components ensures you can maintain, repair or modernise hydraulic lift systems with minimal downtime.

Key Parts Available:

- EV-Series control valves

- KV-Series control valves

- L10 UCM door lock valves

- Rupture valves

- Ball valves

- Coils

- Flow guides

- Pumps and motors

- Hydraulic oil tank heaters

- Hand pumps

- Seal kits

- Pressure and temperature sensors, and more!

Partner with Whitesmith Solutions for peace of mind — access the right parts first time, with prompt delivery across New Zealand, Australia, and throughout the South Pacific.

Blain EV‑Series Control Valves

Smooth, Adjustable Dual‑Speed Valve Technology from ¾″ to 2½″ for Optimal Ride and Safety

Blain’s EV‑Series mechanical control valves have been setting the global standard in hydraulic elevator control for over 50 years. Designed and manufactured in Germany under rigorous quality protocols, these valves feature patented pilot‑compensated up‑levelling systems for precise, reliable performance across extreme loads and temperature variations.

Key Features:

- Size Range: Available in ¾″, 1½″, 2″, and 2½″ port sizes, accommodating flow rates from 10 to 1530 l/min

- Adjustable Dual‑Speed Operation: Offers customizable full‑speed and creep‑speed control both up and down, with EV0/EV1 models providing single up‑speed (0.16 m/s) and EV10/EV100 offering two‑stage up‑speed (0.16 m/s & 1 m/s)

- High Pressure & Safety: Operates up to 100 bar (1450 psi), with burst ratings from 340–575 bar and built‑in relief/back‑up valves for safety and stability

- Robust & Reliable: Self‑cleaning filters, hardened bores, continuous‑duty solenoids (IP68), and temperature‑compensated pilots ensure low maintenance and long service life

- Smooth Ride Quality: Engineered for exceptional ride comfort and precise stopping accuracy, even under full load or temperature extremes

Blain KV‑Series Control Valves

Compact, Reliable Valves for Freight Lifts and Small Industrial Applications

The Blain KV‑Series mechanical control valves offer reliable, compact hydraulic control tailored suitable for freight lifts and smaller industrial applications.

Key Features:

- Single up-speed, adjustable down-speed: Ensures consistent lifting and smooth descent

- Integrated safety features: Built-in check valve, pressure relief, emergency release, and shut-off functions enhance system protection

- Flexible port sizing: Cylinder & tank at ⅜″, pump connection options at ¼″, ⅜″, and ½″ for versatile installation

- Sturdy German engineering: Rated up to 130 bar operating pressure and IP68 solenoids ensure durability and reliability

Blain GV‑Series Control Valves

Single Up-Speed and Adjustable Down-Speed with Built-In Safety Features

The Blain GV‑Series control valve is a versatile solution for hydraulic car parking systems, platform lifts, small goods, dumbwaiters and cargo lifts. Engineered in Germany with robust construction, these valves offer dependable, low-maintenance performance.

Key Features:

- Flow range: 1-24 l/min, up to 130 bar

- Supplied complete with integrated check valve, pressure relief valve and emergency release

- Constant lifting speed and adjustable lowering speed

- Compact and lightweight — easy to install in tight spaces

- IP68-rated for dependable performance

- Proven German quality and reliability

Blain EV40 VVVF Control Valve

Energy-Efficient, Smartphone-Controlled VVVF Technology

The Blain EV40 brings cutting-edge VVVF (Variable Voltage Variable Frequency) technology to hydraulic lifts, combining efficient performance with intuitive smartphone control for simplified commissioning and maintenance.

Key Features:

- Significant Energy Savings: Reduce lift energy consumption by up to 65% and oil heating by up to 50%, lowering operating costs and extending system life

- Smartphone Control: Monitor, adjust, and commission the valve easily via Wi-Fi and the Blain app — no need for machine-room access

- Quick Modernisation: Retrofit existing EV100 or mechanical valves in under 10 minutes with Blain’s plug-and-play kit

- Smooth, Precise Ride: VVVF-controlled up travel provides consistent, quiet performance under variable loads and temperatures

- Built-In Safety & Reliability: Includes overload protection, smart motor-pump management, and robust German engineering for dependable operation

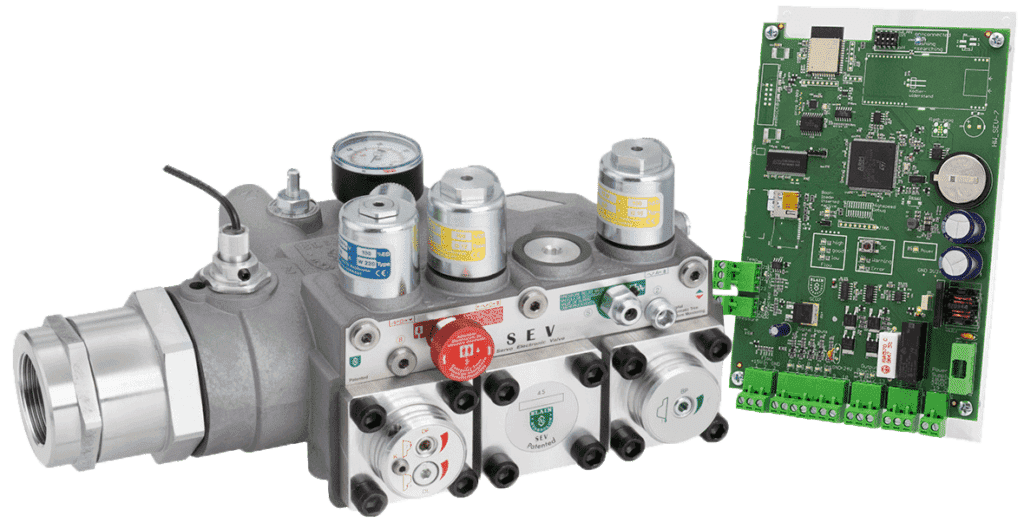

Blain SEV Control Valve

Wi‑Fi Programmable Valve with Closed‑Loop Sensors for Precise Travel

The Blain SEV‑Series is a fully electronic servo valve for hydraulic lifts, combining advanced closed‑loop control with smart Wi‑Fi programming for exceptional ride comfort and performance. Ideal for modern high-traffic passenger lifts, the SEV automatically adjusts flow and pressure for smooth, precise operation in all load and temperature conditions.

Key Features:

- Precision Ride Quality: Closed-loop electronic sensors constantly adjust acceleration, deceleration, and speed for consistent, comfortable travel — no matter the oil temperature or load.

- Smart Wi‑Fi Programming: Easily set up, monitor, and adjust performance profiles using your smartphone or laptop, with remote diagnostics for added convenience.

- Quiet & Smooth: Turbulence suppression and sensor compensation ensure near-silent valve operation and seamless ride transitions.

- Built-In Safety: Self-closing manual lowering, self-cleaning filters, overload protection, and IP68-rated solenoids provide maximum system reliability and safety.

- Flexible Flow & Pressure: Available in multiple port sizes (1″ to 2½″) for flows up to ~1,200 l/min and operating pressures up to 60 bar, making it suitable for a wide range of hydraulic lift applications.

- German Engineering: Designed and built to the highest quality standards for long-lasting performance with minimal maintenance.

Blain L10 UCM (Door Lock) Valve

Solenoid‑Controlled Safety Valve for Hydraulic Elevators

The Blain L10 UCM Valve—also known as the Pressure Lock or Door Lock Valve—is a solenoid-operated check valve designed to enhance safety by preventing unintended downward car movement when elevator doors are open. It allows unrestricted oil flow from the pump unit to the cylinder during upward travel, while the solenoid locks reverse flow once energized, bolstering the main control valve’s safety system.

Key Benefits:

- Unintended Car Movement Prevention: Blocks unintended descent during door-open conditions

- Reduces Cylinder Bounce: Minimizes bounce due to oil compressibility when mounted close to the cylinder

- Manual Emergency Lowering: Features a self-closing valve with manual override for safe descent during power loss

- Slack Rope (LK) Compatibility: Can integrate Blain’s optional slack rope valve for roped hydraulic systems

- Universal Mounting: Suitable for direct installation adjacent to main control valves in any pipe size or position

- EN 81‑2 / TÜV Safety Certified: Meets international hydraulic lift safety standards

- Available in sizes ½” to 2 ½” to suit a wide range of lift configurations

Blain R10 Rupture Valve

Adjustable Safety Valve for Sudden Pipe Failure Protection

The Blain R10 Rupture Valve is a critical safety device for hydraulic lifts, engineered to detect and stop uncontrolled downward movement caused by pipe rupture or excessive descent speed. Installable in any orientation directly on the cylinder inlet, it closes automatically when pressure drops or flow exceeds a set threshold, bringing the elevator to a smooth, secure stop.

Fully compliant with EN 81 lift standards, the R10 is durable, easy to adjust, and ideal for both new installations and system upgrades.

Key Features:

Immediate response to pipe rupture or over-speed: Automatically closes when cylinder line pressure drops or downward flow exceeds the preset threshold—ensuring smooth, safe stops

Adjustable closing flow: Customizable trigger rate via a top-mounted screw to match hydraulic flow requirements

Optional controlled lowering function: With the “lowering speed” option, post-trip descent continues at a controlled rate—ideal for safe cabin evacuation

Dual-cylinder synchronization: Pilot port (“DK” option) allows multiple R10s in twin-cylinder setups to close simultaneously for balanced safety

Safety-limit switch available: Optional "ES" electrical limit switch signals the controller to trigger alarms or shut down once the valve trips

Mountable in any orientation: Designed for direct installation on the Z-cylinder inlet; universal orientation simplifies retrofits

Wide range of sizes and pressure ratings: Available in sizes from ¾″ to 3″, handling flows from ~5 to 2,100 L/min and pressures up to 1,500 psi

Smooth deceleration under 1 g:

Provides gentle slowdown, minimizing jolts and improving passenger comfort

Blain TH Tank Heater

Thermostatic Heater to Maintain Optimal Hydraulic Oil Viscosity

The Blain TH Tank Heater is a rugged, thermostat-controlled heating unit engineered for hydraulic lift tanks (and similar systems) to maintain oil temperatures within the optimal range of +20 °C to +25 °C (or optionally +15 °C to +35 °C).

Ideal for environments prone to low ambient temperatures or long idle periods, the TH ensures consistent oil viscosity, prevents condensation, and avoids premature aging—all crucial for reliable and safe elevator performance. Designed to handle up to 500 L of hydraulic oil, it combines efficient heat distribution with robust German engineering to safeguard system integrity.

Key Features:

- Precise Temperature Control: Thermostat automatically switches heater ON at ~20 °C and OFF at ~25 °C (adjustable range up to +35 °C), ensuring consistent oil viscosity.

- Protects Oil from Degradation: Maintains oil above critical thresholds to prevent oxidation and premature aging, extending component lifespan

- Condensation Prevention: Eliminates moisture condensation within the tank, preventing corrosion and preserving hydraulic cleanliness

- Large Heating Area, Safe Surface Temperature: Housing keeps surface temperature below +50 °C to avoid overheating, even when exposed to ambient temperatures

- High Capacity for Larger Tanks: Designed to effectively heat tanks holding up to 500 L (130 US gal), ideal for machine rooms or cold environments

- Robust Build Quality: Engineered with German precision, featuring durable housing and integrated safety – ensures reliable operation in demanding elevator applications

- Plug-and-Play Installation: Simple to install and integrate into existing tank setups; mounts low for optimal heat circulation.

Blain EN Emergency Power Coil

Emergency Solenoid Coil for Safe Lowering During Power Outages

The Blain EN Emergency Power Coil is a vital safety accessory for hydraulic elevators, designed to activate the emergency lowering function when main power is lost. Available in 12 V or 24 V AC/DC versions, this coil ensures that passengers can be safely brought to the next floor during a blackout—meeting modern safety regulations for emergency access and evacuation.

Key Features:

- Automatic emergency lowering activation: Triggered by secondary 12 V or 24 V AC/DC supply, the coil engages the lowering system during power failure to safely guide the elevator car to the nearest floor

- Versatile voltage compatibility: Choose between standard models for <100 V systems (4‑wire configuration: Black/Blue/Brown/White) or >100 V systems (5‑wire version with added green‑yellow earth)

- Safety-compliant design: Meets current hydraulic elevator safety standards, essential where elevator access is critical for emergency services

- Easy specification and integration: Simply specify your main and emergency voltages when ordering; designed for smooth integration with existing Blain control valves

- Reliable and low-maintenance: Heavy-duty construction ensures dependable performance over time, with straightforward wiring that reduces downtime during installation or service.

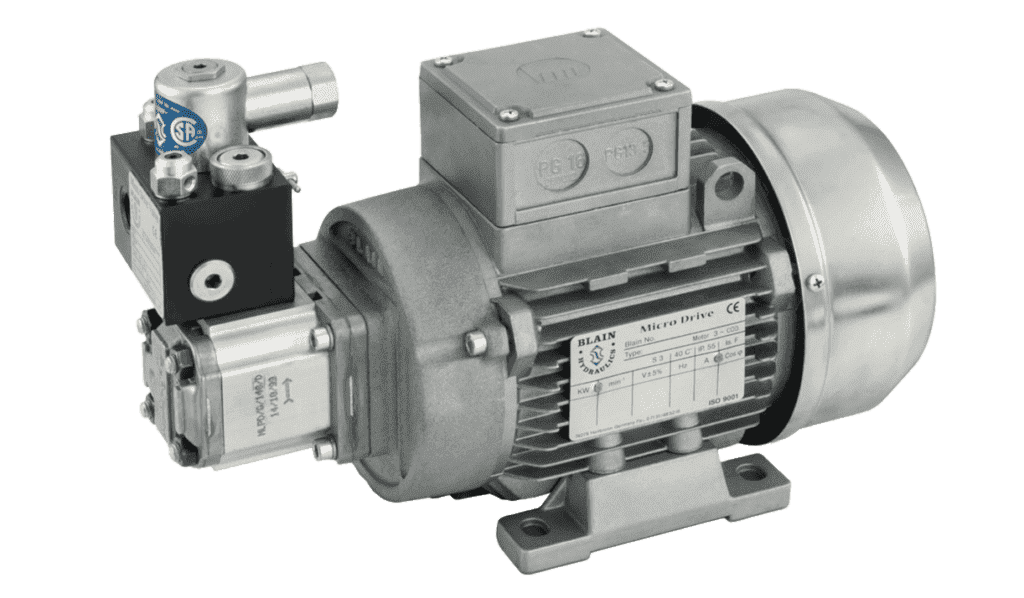

MD Micro Levelling Drive

Precision Micro‑Leveling for Hydraulic & Traction Lifts

The MD Micro Levelling Drive is a compact, motor‑pump‑valve assembly designed for ultra-fine floor positioning in both hydraulic and traction lift systems. Mounted onto the main power unit (or integrated in rope suspension for traction systems), it delivers pinpoint leveling within ±5 mm of the landing. By enabling quiet, efficient micro-movements at ~1 cm/s, the MD Drive enhances ride comfort, allows higher main approach speeds (up to 10 cm/s), and reduces start/stop jerks—all with low power consumption and minimal heat generation.

Key Features:

- Exceptional Stopping Accuracy: Locks the elevator precisely within ± 5 mm of landing, reducing trip hazards and improving ride quality

- Faster Travel Times: Enables main drive to operate at faster speeds (~10 cm/s) while retaining smooth and safe levelling via the micro drive

- Ultra-Quiet Operation: Runs at approx. 1 cm/s for leveling—not noticeable to passengers, ideal for homes, offices, libraries, educational institutes

- Energy‑Efficient Design: Uses low electrical power and prevents unnecessary oil heating by relying on the hydraulic system's existing reservoir

- Enhanced Safety & Smooth Ride: Eliminates jerky starts and auto-corrects for load or air-induced shifts; corrections typically complete in under one second

- Dual‑System Compatibility: Works seamlessly in hydraulic lifts (mounted to hydraulic unit) or as a separate micro-cylinder in traction lifts

- Plug‑and‑Play Integration:

Simple mounting under or on the power unit; connects to existing oil and electrical systems—no extra reservoir or drive needed.

Blain Hand Pumps

Manual Emergency & Testing Pump for Hydraulic Elevators

The Blain HP Hand Pump is a rugged, manually operated hydraulic pump designed for emergency lift operation, system maintenance, and pressure testing. Delivering 13 cm³ of oil per stroke, it includes a built-in pressure relief valve to prevent over-pressurisation. Available in side-mount (H11) or base-plate (H12) versions, it provides flexible installation options—making it essential for safe and reliable hydraulic lift service.

Key Features:

- Emergency manual operation: Allows elevator car movement and descent during power outages or system failures

- Built-in pressure relief valve: Prevents excessive pressure buildup and protects system components—adjustable for safety

- Consistent stroke volume: Pumps exactly 13 cm³ per stroke, ensuring predictable manual control and smooth operation

- Flexible installation formats:

- Side-mount H11: Mounts conveniently on the control valve block

- Base-plate H12: Free-standing or tank-mount option for greater flexibility