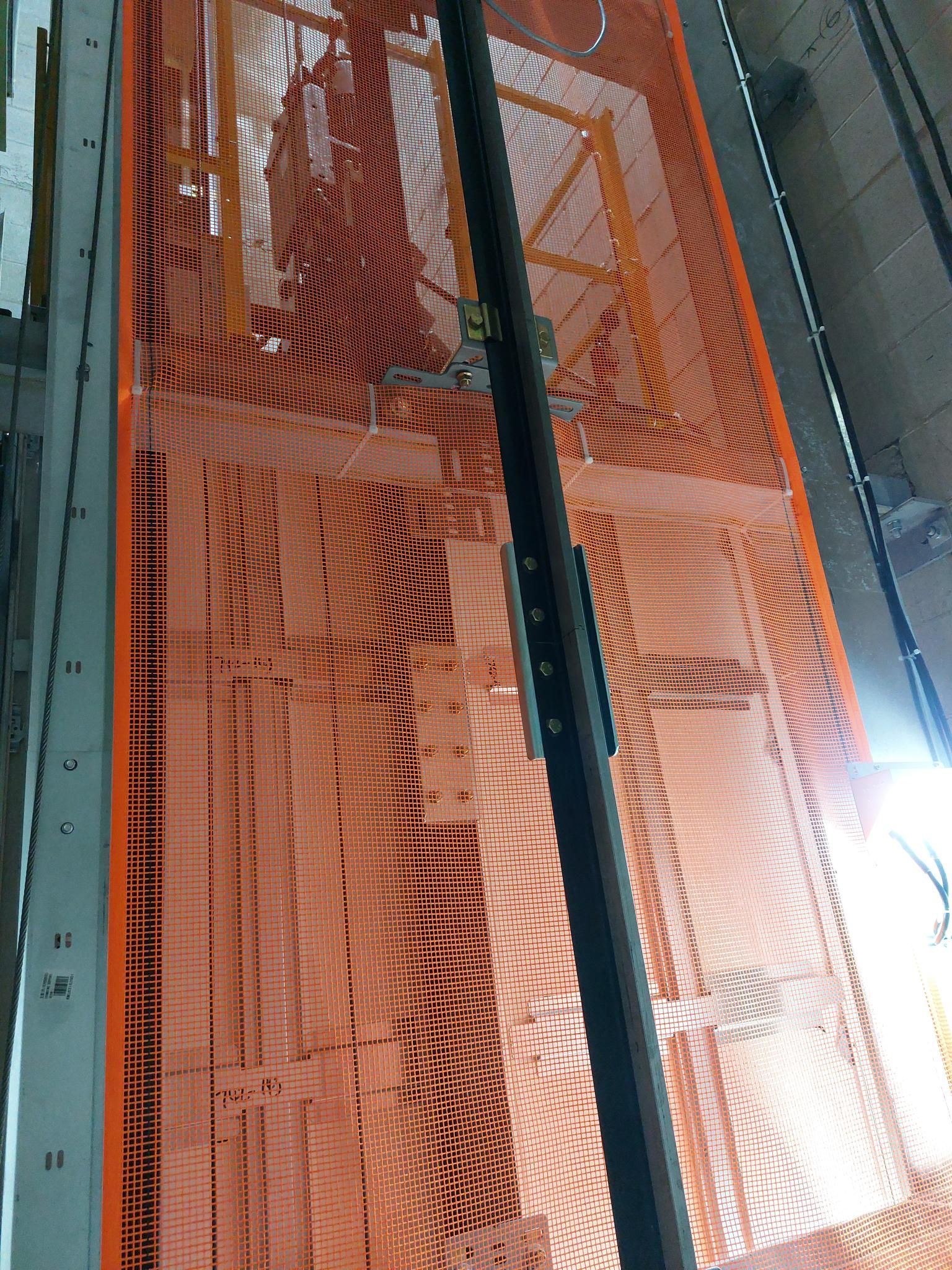

Elevator Shaft Screening & Hoistway Segregation

PearlWeave Safety Netting – Lightweight, Non-Conductive Elevator Shaft Protection

PearlWeave elevator shaft screening is designed to safely segregate shared hoistways, protecting technicians working within one elevator shaft from hazards created by adjacent operating lifts. In multi-car shafts, safety policies adopted by many elevator companies require effective shaft separation before work can proceed — preventing personnel exposure to moving cars, counterweights, or adjacent equipment.

Where no compliant shaft divider or screening is installed, the adjacent lift is often prevented from operating, resulting in downtime, disruption to building occupants, and increased labour costs.

PearlWeave provides a fast, lightweight alternative to traditional steel mesh shaft dividers. It creates a secure physical barrier between hoistways while significantly reducing installation time, minimising lift downtime, and lowering overall project costs.

Manufactured from high-strength, flame-retardant polymer material, PearlWeave is non-conductive, corrosion-resistant, and engineered specifically for elevator shaft environments — making it a safer and more practical solution for both new installations and modernisation projects.

Why Shaft Screening Is Critical

- Prevents accidental access into adjacent operating hoistways

- Protects technicians from moving elevator cars and counterweights

- Supports compliance with elevator company safety policies

- Reduces risk of serious injury within shared shafts

- Allows adjacent lifts to remain operational during maintenance

Key Advantages of PearlWeave Over Steel Mesh

Reduced Installation Time

Lightweight rolls are significantly faster to install than rigid wire mesh panels, reducing labour time and shaft downtime.

Lower Project Costs

Faster installation and less disruption mean lower overall installation costs.

Non-Conductive Material

Unlike steel mesh, PearlWeave does not conduct electricity, improving safety around elevator wiring, travelling cables, and electrical equipment.

Lightweight & Flexible

Weighing approximately 7 kg per roll, PearlWeave is easy to transport and handle within confined shaft spaces.

Fire Retardant & Self-Extinguishing

Flame-retardant properties help limit fire spread and do not release harmful toxins.

Tear Resistant & Durable

Engineered to withstand impact and wear within elevator shafts.

Corrosion & Mildew Resistant

Ideal for damp or enclosed shaft environments where steel mesh may corrode over time.

Ideal Applications

- Shared elevator shafts

- Multi-car hoistways

- Modernisation projects

- Temporary or permanent shaft segregation

- Maintenance works requiring adjacent lift operation